TrueTest™ Automated Visual Inspection Software

Quality testing and defect detection.

When testing the quality of illuminated components and displays, or looking for defects in assemblies and surfaces, multiple tests may need to be performed to inspect products for a range of evaluation criteria. TrueTest™ Software equips ProMetric® Imaging Colorimeters and Photometers to be used for in-line inspection, providing:

- a comprehensive set of predefined tests,

- a flexible framework that allows you to apply a single test or sequence of tests as needed, quickly and efficiently, and

- a pass/fail report with as much detail as you need.

Turnkey System for Automated Visual Inspection

The TrueTest software application has five main components:

- Test library

- Test sequencer

- Test manager (user-defined test parameters and pass/fail settings)

- Test execution, automated

- Report generator

TrueTest is easy to use. Any tests from the test library can be added to a test sequence (these are stored, so multiple sequences can be created and recalled as needed), and test parameters and pass/fail settings are input for each test. Then the entire sequence is run end-to-end automatically. Individual test results are displayed and can be recorded in a report.

Extensive Selection of Built-in Quality Tests

Provided with TrueTest are a range of standard quality tests and defect detection tools, including:

- ANSI Brightness

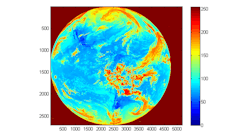

- ANSI Color Uniformity

- Autofocus

- AutoPOI

- Checkerboard Contrast

- Chromaticity

- Color Edge Mura

- Color Mura

- Compare Points of Interest

- Diagonal Pattern Mura

- Distortion

- Focus Uniformity

- Gradient

- Line Defects

- Particle Defects

- Pixel Defects

- Points of Interest

- Polarizer Deformation

- Random Mura

- Sequential Contrast

- Spot Pattern Mura

- Uniformity

Additional advanced mura detection tests are available in the optional TrueMURA™ license. Advanced registration and defect detection for symbols and text is available in the optional VIP™ (Vision Inspection Pack) license.

Designed for High-volume Manufacturing Applications

While TrueTest can be used for diagnostic testing of a device in a laboratory setting, it is designed to meet the demands of high-volume manufacturing applications:

- Supports both an administrator interface for defining tests and test parameters, and a restricted operator mode for running tests

- Interfaces to a video pattern generator or the device under test itself to control test patterns

- Tests initiated by a human operator or directly by a production control system (PCS) in a fully-automated production environment

- Interface to the PCS, a barcode reader, or the equivalent equipment to obtain information about the device under test (DUT); the test sequence and test parameters can be varied automatically from DUT to DUT based on this information

- Takes advantage of the high-speed computing technology of modern PCs to take measurements and perform test analyses in parallel, thereby minimizing cycle time

Field-Proven System for Production Testing

TrueTest Software is used with a ProMetric Imaging Colorimeter or Photometer to create a complete testing system for light quality measurement or machine vision. The specific ProMetric imaging product chosen will depend on your application's requirements for resolution, accuracy, and cost.

When you install TrueTest, Radiant Vision Systems application engineers will work with you to integrate and initialize the system, and train you how to perform those operations and how to maintain the system.

The TrueTest product family is field-proven, with installations worldwide, testing millions of devices for a broad range of products. Once in operation, Radiant will support your integration with our global technical support team and distributor network.